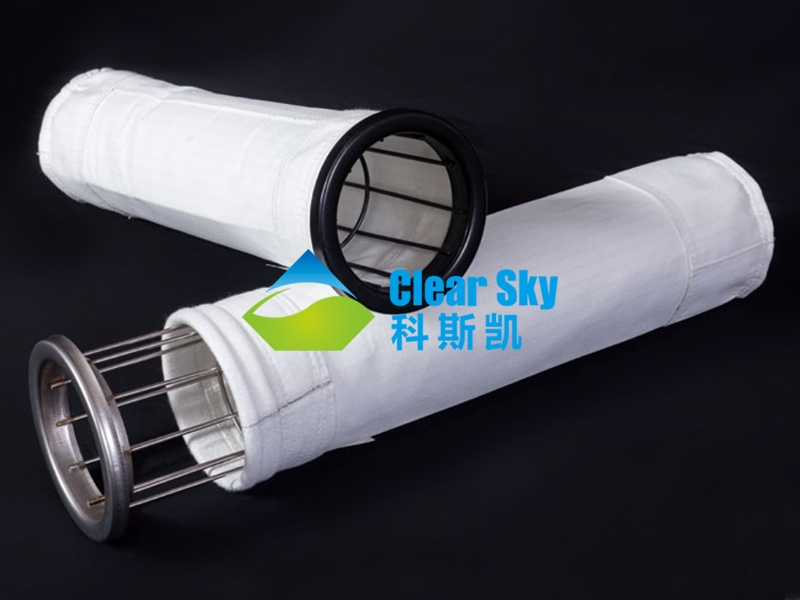

产品说明 Product description

通常工业性粉尘浓度达到一定程度(即爆炸极限)时,如遇静电放电火花或处界点火等因素时,则极易导致爆炸和火灾。如:面粉尘、化工性粉尘、爆炸性粉尘等。如遇静电放电都有爆炸的可性。在袋式除尘领域,如这些粉尘需要用布袋来收集,则要求制做的布袋本身具有防静电功能,生产抗静电滤料除了具备生产普通针刺毡工艺外,还要求在生产针刺毡的基布经纱中并入导电纤维纱。

Usually industrial dust concentration reaches a certain level (that is, the explosion limit), such as the case of electrostatic discharge sparks or other factors such as the ignition point, it is very easy to cause explosion and fire. Such as: flour dust, chemical dust, dust, etc.. In case of electrostatic discharge, there is an explosion. In the field of bag type dust, such as with the bag to collect the dust, it is required to manufacture the bag itself with anti- static function, production of anti electrostatic filter in addition to have the production of ordinary needle felt process, also called incorporated into conductive fiber yarn in the fabric warp yarn production needle felt.

技术参数 Technical parameter

| 名 称 Name | 防静电涤纶针刺毡 Anti static polyester needle felt |

| 材质 Raw material | 涤纶纤维 / 涤纶导电基布 Polyester fiber / polyester conductive fabric |

| 克重 Weight | 450 - 600g/㎡ |

| 透气性 Air permeability | 200 - 300L/㎡ ·s@200Pa |

| 径向拉力 Radial pull | 800 - 1200N/5x20cm |

| 纬向拉力 Weft Tensile Strength | 1000 - 1600N/5x20cm |

| 径向伸长 Radial elongation | <35% |

| 纬向伸长 Weft elongation | <55% |

| 电阻表面 Resistance Surface | 4.8 |

| YX10 体积 YX1O Volume | 8.7 |

| 摩擦电位 最 大值 Frictional potential Maximum value | 250 |

| V 平均值 V Mean value | 183 |

| 面电核密度 me/㎡ | 3.4 |

| 使用温度 Use temperature | ≤ 130° C |

| 过滤风速 Filtration velocity | 1.0-1.2m/min |

| 后处理方式 Post processing method | 烧毛、压光、热定型 Singeing, calendering,heat setting |

(表格可左右滑动)